Filtration Solutions

Solving Fuel & Oil Contamination Challenges

We Solve Real Problems

Innovative Filtration Solutions

Smart Filtration Solutions is all about taking your preventive maintenance practices to the next level. Our goal is to help you protect your bulk fuel storage tanks, your fuel, and your expensive equipment by refusing entry of harmful contaminants. We offer Ultra High Efficiency Filters that fit on our innovative square tube manifolds & filter heads to accept high flow rates and extend service life. Our solutions help you deliver clean fluids into your equipment and maximize your uptime. Require a fraction of the capital expense compared to traditional pressure housings and cartridge elements.

Technical Proposals

We'd love to share our knowledge and experience

We provide value-added services through assistance with design, commissioning and the selection of a customized filtration solution. A comprehensive after-sales support provides advice, recommendations, condition monitoring, technical assistance and spares.

● Onsite surveys to determine the best solution for your operation.

● Value added services of condition monitoring and analysis.

● Contamination control training.

Site Visits

Unlike our competitors, our top priority is for our engineers to physically visit customer sites instead of designing/suggesting filtration solutions via email. Once our filtration solution is approved and shipped, we provide guidance during the installation followed by site visits for commissioning of the installation. Follow up visits are scheduled to monitor and maintain the efficiency of the filtration solution.

We Solve Real Problems

Smart Filtration Approach

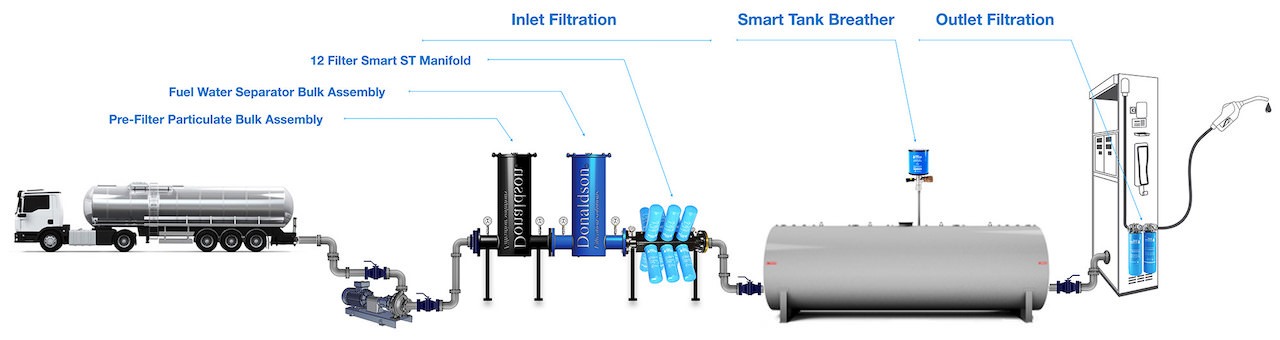

Inlet Filtration

We highly recommend filtration to be focused at the delivery of fluids. At this point, flow is steady with minimal disruptions and vibrations. This scenario results in the highest filtration efficiency and reduces the risk of contamination built up in storage tanks. Designed for high flow rates and minimum pressure drop, our Ultra High Efficiency Filters form a strong line of defense in ensuring enhanced cleanliness of fluids.

Smart Tank Breather

It is very likely that your fuel/oil storage tank has a U shaped open vent at the top. What your storage tank really needs is a Smart Tank Breather. The T.R.A.P. (Thermally Reactive Advanced Protection) Breather is a self-regenerating moisture removal system with integrated dust removal. Its dual function is to capture the moisture on the inhalation phase and release it with each exhalation so that water contamination is prevented continuously.

Outlet Filtration

If you stop introducing contaminants into the tank and stop them from coming in with a Smart Tank Breather, contaminants will stop coming out. Over time, the outlet filtration will rarely need service and the inlet filtration will be the primary service item on the system. But outlet filtration is still highly recommended to maintain cleanliness achieved at inlet filtration, as this is the last and most critical point to capture microscopic dirt particles & water before they make their way to the expensive and delicate components of fuel injection systems.

Modern Engines Demand Clean Fuel

Progressive introduction of increasingly stringent emission standards have resulted in sophisticated diesel engines that require cleaner fuel than ever before to operate efficiently, due to injection pressures of more than 30,000 PSI and extremely tight tolerances. In engines where precision is everything, you can’t risk the damage done by high-velocity microscopic contaminants. At 30,000 PSI (2000 BAR), every unfiltered particle acts almost like a tiny sandblaster, eroding the injector, creating inefficient spray- patterns and potentially over-fueling the engine. A fouled injector doesn’t spray fuel efficiently and may lead to improper idle, irregular fuel distribution, unsuitable exhaust emissions and poor fuel economy.

We Have Great Answers

Frequently Asked Questions

Common rail injector’s pressure can go up to 2700 BAR. This increase in pressure has a major impact on the cleanliness level of the fuel that is allowed to flow through the injector.

We always stress the fact that the main aspect to consider in choosing a filtration unit is the balance of efficiency, capacity and pressure drop. There are many factors to consider when it comes to dirt holding capacity: flow, viscosity, system pressure drop, contaminant properties, etc. All these factors have an impact on the dirt-holding capacity of a filter.

If you get a bad batch of fuel, a kidney loop system will then have to recirculate the entire volume of what was in your tank + the new delivery. A kidney loop system cannot physically clean all fluid in the tank; there is always a point of zero gravity that a kidney loop system will not filter. Start – Stop principle that is frequent at a kidney loop releases small particles.

As long as tanks are interconnected and have one main inlet, it doesn’t matter how many tanks you have on site. We carefully design and size up the installation to coup with service intervals. Some of our end users have up to 8 fuel tanks connected to a single manifold on the inlet side.

Smart Filtration Solutions gives you 100% control over the cleanliness of fuel you receive. Many people assume they are buying quality fuel that meets the required specifications; diesel fuel cleanliness is rarely questioned. But higher fuel systems operating pressures, lower system tolerances and tighter filtration have pushed fuel cleanliness into the maintenance spotlight.

Normally, laser and automated white light particle counters are used to detect the contamination that is present in fluids. It may happen that these particle counters are not accurate and count phantom particles because of the difficulty in differentiating dirt, water or additives. Phantom particles count is more present in fluids blended with additives than in base fluids.