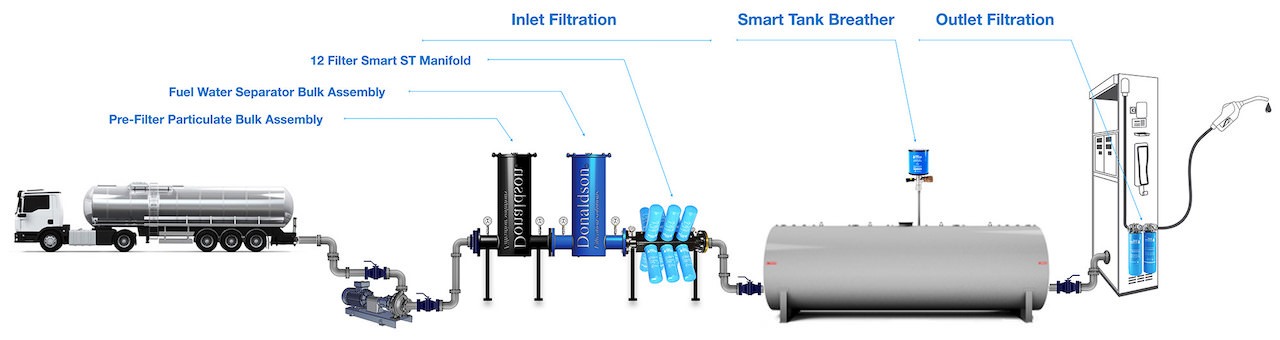

Our Product Line

Solving Fuel & Oil Contamination Challenges

Smart Tank Breather

Smart Tank Breather element contains Donaldson’s revolutionary T.R.A.P.™ (Thermally Reactive Advanced Protection) Technology that reduces the risk of dust and moisture entering storage tanks through the vent while allowing high flow rates of fluid into and out of the tank.

T.R.A.P.™ breathers contain a deliquescent drying agent that captures humidity from the air as it is drawn into the reservoir. Warm, dry air exiting the reservoir removes moisture from the deliquescent material, so T.R.A.P.™ breathers last longer than desiccant breathers.

Smart Tank Breather

To be used on bulk storage tanks containing diesel, lube, hydraulic, engine or transmission oil.

Features & Benefits:

- Airflow up to 500 gpm/1893 lpm

- Filter efficiency > 97% at 3µm

- Service restriction indicator

- Efficient moisture removal

- Inhibits corrosion

- Easy installation spin-on replacement element

- Retards microbial growth

- Safety overfilling valve

Installation instructions:

One unit recommended for tanks up to 40,000 liters*

Multiple units for tanks larger than 40,000 liters*

Breather element to be changed on restriction or every 4 months.

* For information on meeting API 2000 or other tank design requirements, please contact us.

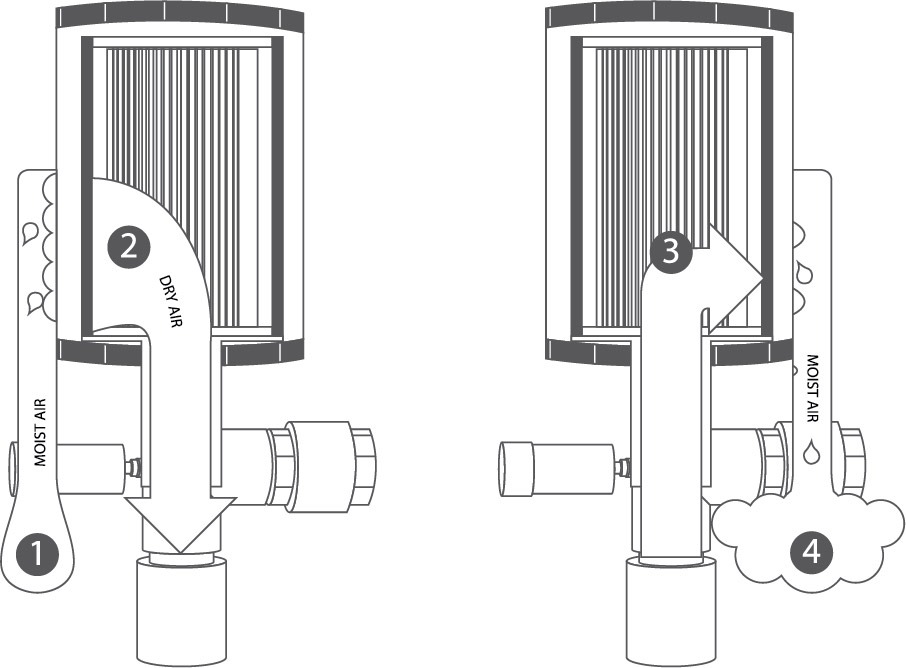

How Smart Tank Breather Works

Intake Cycle (Inhalation)

1) The circuit “breathes in” air containing moisture vapor.

2) The T.R.A.P.™ breather strips moisture and particulate from the incoming air allowing only clean, dry air to enter the circuit.

Outflow Cycle (Exhalation)

3) During the “exhalation” cycle, the T.R.A.P.™ breather allows unrestricted airflow outward.

4) The outflow of dry air picks up the moisture collected by the T.R.A.P.™ breather during intake, and “blows it back out” – fully regenerating the T.R.A.P.™ breather’s water-holding capacity.

Modern Engines Demand Clean Fuel

Progressive introduction of increasingly stringent emission standards have resulted in sophisticated diesel engines that require cleaner fuel than ever before to operate efficiently, due to injection pressures of more than 30,000 PSI and extremely tight tolerances. In engines where precision is everything, you can’t risk the damage done by high-velocity microscopic contaminants. At 30,000 PSI (2000 BAR), every unfiltered particle acts almost like a tiny sandblaster, eroding the injector, creating inefficient spray- patterns and potentially over-fueling the engine. A fouled injector doesn’t spray fuel efficiently and may lead to improper idle, irregular fuel distribution, unsuitable exhaust emissions and poor fuel economy.

We Have Great Answers

Frequently Asked Questions

Common rail injector’s pressure can go up to 2700 BAR. This increase in pressure has a major impact on the cleanliness level of the fuel that is allowed to flow through the injector.

We always stress the fact that the main aspect to consider in choosing a filtration unit is the balance of efficiency, capacity and pressure drop. There are many factors to consider when it comes to dirt holding capacity: flow, viscosity, system pressure drop, contaminant properties, etc. All these factors have an impact on the dirt-holding capacity of a filter.

If you get a bad batch of fuel, a kidney loop system will then have to recirculate the entire volume of what was in your tank + the new delivery. A kidney loop system cannot physically clean all fluid in the tank; there is always a point of zero gravity that a kidney loop system will not filter. Start – Stop principle that is frequent at a kidney loop releases small particles.

As long as tanks are interconnected and have one main inlet, it doesn’t matter how many tanks you have on site. We carefully design and size up the installation to coup with service intervals. Some of our end users have up to 8 fuel tanks connected to a single manifold on the inlet side.

Smart Filtration Solutions gives you 100% control over the cleanliness of fuel you receive. Many people assume they are buying quality fuel that meets the required specifications; diesel fuel cleanliness is rarely questioned. But higher fuel systems operating pressures, lower system tolerances and tighter filtration have pushed fuel cleanliness into the maintenance spotlight.

Normally, laser and automated white light particle counters are used to detect the contamination that is present in fluids. It may happen that these particle counters are not accurate and count phantom particles because of the difficulty in differentiating dirt, water or additives. Phantom particles count is more present in fluids blended with additives than in base fluids.